Today, let’s talk about 3D printing, something many of us know about! Originally, it was used a lot in designing things like machines. Now, it’s being used to create cool stuff in fashion, like jewelry and clothes. For instance, a well-known 3D designer from the Netherlands, Janne Kyttanen, made shoes that you can print in just one night!

Also, there’s this unique dress worn by the dancer, Dita Von Teese, which was made with a 3D printer. Frances Bitonti designed it, working with a company named Shapeways. The dress fits her perfectly and has a neat grid-like structure that makes it easy to wear. It’s not just a piece of clothing; it’s also a piece of art!

3D printing allows for great detail and craftsmanship, especially for custom-made items. I’ve looked into how it’s being used in the jewelry industry and analyzed its application. So, let’s dive deeper into this innovative technology together!

1. What is 3D Printing?

3D printing technology refers to “a technology that uses digital model files as a basis and uses adhesive materials such as metal or plastic to construct objects by printing layer by layer.

2. The Working Principle and Specific Implementation Steps of 3D Printing Technology

To comprehend 3D printing technology, it’s beneficial to look at its origins, which date back to the 1990s. Fundamentally, modern 3D printers work on a principle similar to conventional printers. These printers are connected to a computer and utilize either liquid or powdery material as the “ink.” The computer controls the layer-by-layer deposition of this material to create a three-dimensional object.

Each layer’s creation involves a two-step process.

- First, a specialized adhesive is sprayed on the areas that need to form the object.

- Next, a layer of powder, which acts as the printing material, is spread evenly over the adhesive. The powder bonds with the glue and solidifies, while the areas without adhesive remain in a powdery state. By alternating between layers of adhesive and powder, a three-dimensional object is crafted.

However, if the objective is to create intricate items like jewelry, merely having a 3D printer is insufficient. A 3D CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) system is essential. In this context, CAD refers to the software component responsible for the design, while CAM refers to the hardware used for production, including the 3D printer itself.

During the design phase, the designer uses CAD software to translate the two-dimensional blueprints into a three-dimensional model. Post this step, the computer running the CAD software is connected to the CAM hardware, which, in turn, executes the printing process based on the 3D model.

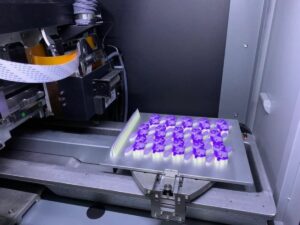

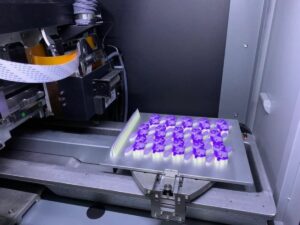

CAM equipment, often referred to as 3D printers, plays a vital role. Controlled by a computer, these machines execute a series of tasks to create three-dimensional objects. Typically, in jewelry prototyping, these objects are wax or resin models. Successful 3D printed pieces necessitate a combination of excellent design skills, adept software operation, and a coordinated effort between the printing materials and the printer itself.

3D printing technology has gained significant traction in the jewelry industry, particularly in the design phase. Various CAD software options are available, each with its unique features and applications. Among the most widely used are Vision 3Design by the French company Mumeric, Matrix by the American company Gemvision, and Jewelcad developed by a Hong Kong-based company.

In jewelry production, focusing on Jewelcad, it’s a professional CAD/CAM software specifically crafted for jewelry design and manufacturing. Here are some of its characteristics:

It is convenient and flexible to create and modify curves and surfaces. It has powerful modeling functions and can be applied to complex applications.

- There are fixed design libraries, such as gem reserve library, parts library and user library, which can be extracted directly. You can also create a database to store some models you have made so that you can use them next time for direct application.

- There are a large number of material libraries set for jewelry materials. Materials can be added after the modeling is completed. Render and output high-quality color images quickly and easily. At the same time, you can also use the material changes in data, adding and changing materials.

- Allows 3D view processing of models, output standard GM coding and STL in CNC machining Data, output standard seamless STL and SLC data to quickly create models.

- The software also has the function of calculating gold weight.

- In fact, other software also has its own characteristics. These features make it easier for us to draw three-dimensional jewelry and model diagram. However, the core of any successful design still rests on the designer’s ability to think creatively and utilize the software effectively.

3. Advantages of 3D Printing Technology

Efficiency

3D printing technology has greatly improved work efficiency. This technology is quick to form, and for some materials quality can even produce finished products directly.

Improved Accuracy

In traditional jewelry design, artisans usually rely on hand-carved wax models, making the end product dependent on manual measurements and the skill level of the wax carver. 3D printing technology, on the other hand, allows for precise computer-generated models.

Designers can input data directly into CAD software and produce a 1:1 physical output via CAM equipment. This enhances overall accuracy and allows for greater customization to meet individual customers’ physical specifications.

Reduced Work Costs

Traditionally, the design phase of jewelry production often necessitates the creation of physical molds or samples to visualize the finished product. However, 3D software can simulate various materials and generate digital renderings, thereby eliminating the need for physical samples. This reduction in material and labor costs leads to a lower rework rate, ultimately driving down production costs.

Enhanced Design Versatility

As consumers increasingly seek unique and personalized jewelry that reflects their personality and values, designers face the challenge of creating innovative pieces that go beyond simple gold or silver accessories. 3D design software provides the tools to create complex, vivid, and flowing designs efficiently. This would be difficult to achieve with traditional manual methods.

Efficient Budgeting

One of the significant perks of using 3D software for jewelry design is the ability to calculate the precise amount of materials needed, including the weight of gold or other metals. This feature streamlines the jewelry-making process by providing an accurate budget upfront, reducing the risk of over-spending on materials.

Easy Design Modifications

3D models and digital renderings offer a realistic view of the final jewelry piece, allowing both designers and consumers to assess the design closely. Should any deviations or improvements be needed, modifications can be made effortlessly and quickly in the software. This enables real-time adjustments without the need to start over or waste materials.

4. Limitations of 3D Printing Technology

| Limitation |

Description |

| Limited Material Options |

Few materials available for printing, restricting the variety of products. |

| Layer Resolution Constraints |

Visible layers on printed objects; challenging to achieve high-resolution details. |

| Build Size Restrictions |

Limited size of objects due to printer constraints; large items may need assembly. |

| Time-Consuming Process |

Printing intricate or large objects can be slow, unsuitable for urgent needs. |

| Post-Processing Requirements |

Objects often require additional finishing efforts like sanding or painting. |

| Material Strength Issues |

3D printed parts may lack strength and durability, especially for industrial use. |

| Limited Mass Production Scalability |

Inefficient and costly for large-scale manufacturing compared to traditional methods. |

| Complex Design Expertise Needed |

Requires technical knowledge; complex designs demand skilled professionals. |

| Copyright and IP Concerns |

Raises concerns about unauthorized reproduction of copyrighted designs. |

| Environmental Impact |

Production materials can have environmental impact; disposal of objects adds to plastic waste. |

- 3D printing technology has not yet gained widespread acceptance in the jewelry industry, largely due to limitations in the types of materials that can be used. Currently, 3D printing is most commonly used to create initial wax models. These models then go through traditional manufacturing processes such as casting, grinding, and polishing.

The range of materials for 3D printing is generally limited to wax, resin, and plastics. Using metal materials is cost-prohibitive and not easily implemented. In addition , due to the high risks in printing material research and development and supply, as well as high technical requirements. Characteristics, the field of 3D printing has not yet formed a complete and orderly industrial chain, so the current.

- Second, I’ve noticed that in some Beijing jewelry studios using 3D printing technology, the staff typically don’t have specialized art design training. They usually assist designers by creating basic drawings since the designers, while responsible for drawing, don’t know how to use the software. This separation makes it hard to blend design and operation, hindering the growth of 3D digital jewelry design.

Although 3D printing technology is advanced, it’s mainly used to support jewelry performances. The essential element remains the designer’s creative thought process. For designers, while 3D printing is a crucial tool for showcasing their ideas, it’s not the only thing that matters. Ideally, modern designers should integrate both design thinking and operational skills

5. Development Directions of 3D Printing Technology

Janne Kyttanen, a well-known figure in modern 3D printing design, shared some profound insights in an interview with Dezeen magazine. He foresees that 3D printing will become commonplace in numerous homes, altering our lifestyles and our roles as consumers.

According to Kyttanen, people won’t simply be buyers in the future; everyone will have the potential to be a designer, crafting their own items. Professional designers, he suggests, will pivot towards creating superior design models for widespread use. He strongly believes that 3D printing isn’t about selling physical items, but rather, it is about marketing creativity.

In our era of advancing production technology, making items has become quicker and more convenient through various technical approaches. Kyttanen points out that our attention should therefore shift increasingly towards design, pondering on how we can leverage modern technology to boost our creative thought. This, he feels, is a vital consideration for today’s jewelry designers.